We followed a Bovet watch from concept to creation, and learned why people buy them

Zach BlassAndrew visited the Bovet manufacture, located within the Castle of Môtiers in the canton of Neuchâtel, Switzerland, to get a first-hand experience of what it feels like to commission a bespoke watch from the House of Bovet – which we have previously written an in-depth history of Bovet right here. In the video, Andrew will walk you through the process – from concept to creation – and highlight his favourite moments of watching the completion of a Bovet watch in-house from A to Z. Then, Andrew meets with Bovet Fleurier SA Owner Pascal Raffy, as any of their clients would have the privilege of being able to do, to be presented with the final watch. In this story, you can read some of the key points from his visit. But I strongly urge you to head straight into the video below for the full experience.

Bovet limits annual production to around 1,000 watches per year – 30% of which are bespoke

While companies like Rolex and Omega make hundreds of thousands or a million watches per year, and big-name independents like Audemars Piguet make approximately 50,000 watches or more per year, Bovet limits their production to just around 1,000 pieces annually – in line with manufactures like F.P. Journe. But of these 1,000 or so watches, over 30% of these creations annually are bespoke commissions. This scale of production is not just, in some respects, necessary due to the amount of detail and work that goes into the creation of a Bovet watch. It is a choice that affords Bovet the freedom to indulge their clients with bespoke commissions. And the wide breadth of what they can realise is a result of being among the few truly vertically integrated watch manufacturers.

Bovet is one of less than ten manufacturers to make their own hairsprings

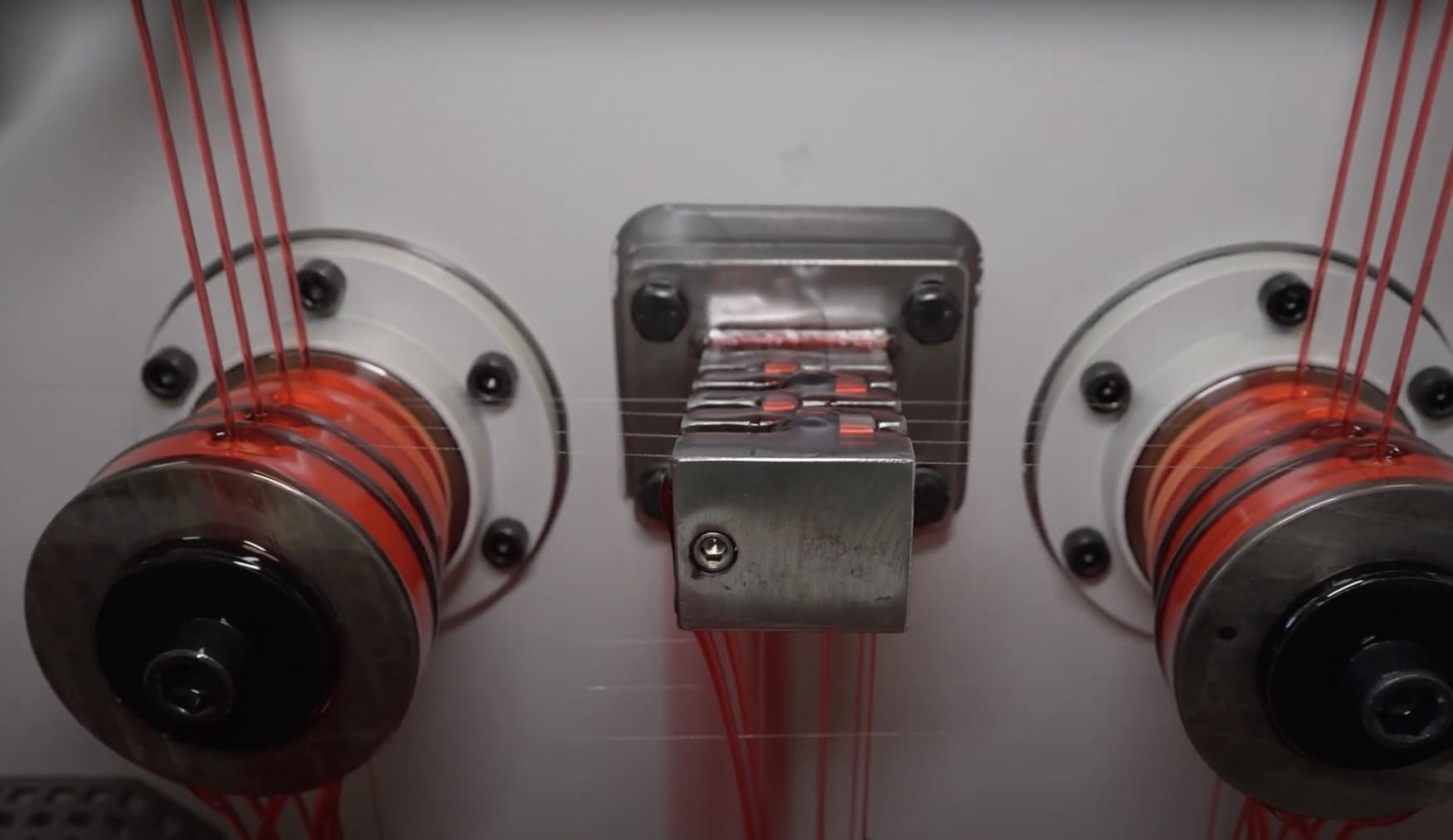

Bovet are one of less than ten companies in the world that can manufacture a hairspring themselves. A rather unglamorous yet incredibly crucial component of any timepiece, the hairspring is an incredibly small piece of coiled material that functions within the heart and regulating organ of a watch: the escapement. The oscillations of the balance wheel are ultimately driven by the hairspring, uncoiling and recoiling at a precise rate – without it, a mechanical watch would not keep time. To create this crucial component, imagine a guitar string and then stretch it in your mind to the point where it is as thin or thinner than a human hair.

This is what Bovet has mastered in-house, taking an exact alloy of steel and putting it through a stretching process through five rings multiple times to reduce the thickness. This is performed nine times across 45 rings to reduce it down to the size of the final hairspring we see within the watch. With the hairspring made in-house, it then allows the watchmaker to tailor-weight the balance wheel so that it is perfectly weighted for that particular hairspring. This is a process that is best understood visually, rather than read. So, again, definitely watch the video back at the top.

Bovet makes all of their dials in-house

Most watch brands turn to specialists to make their dials, but Bovet, as a vertically integrated manufacture, creates their dials in-house. Andrew was mesmerised by the vast array of options to choose from, and the many unusual and uncommon dial configurations to explore. Yes, they of course have traditional guilloche dials in all kinds of different colours.

But Andrew was particularly taken aback by a mother-of-pearl dial with the difficult craft of miniature painting on its surface. Just about any colour or treatment you can think of Bovet can do it, and this allows clients to receive something very unique regarding a part of the watch many believe is the most important part of the watch: its face.

Exquisite engraving that can require a week for just one movement

Andrew would eventually land on the Virtuoso XI to be the timepiece for his journey as a pretend client. This was because he was absolutely gobsmacked watching the engraver at work on the bridge plate of the movement. With such a skeletonised watch, from afar it is hard to fully understand the rich craft at play here. In Star Wars, when the Death Star is visible in the distance of outer space you see a massive sphere. It is only when the rebels launch an assault on it that you realize there are all these channels and details on its surface.

So, when you are in a position like Andrew, at the manufacture, and able to see the work happen in real-time on a macro scale, it is absolutely mindblowing what these master engravers are able to perform by hand. A. Lange & Söhne, for example, free-hand engrave the balance cock of their movements. But, Bovet, among a few others who can do it well, takes the time in certain creations to engrave effectively the entire surface real estate of the calibre – even extending these motifs to be engraved on the case as well. According to Pascal Raffy, the Virtuoso XI’s calibre takes a full week to decorate. This is something brands who mass produce watches do not have the time, or the skilled artisans, to undertake.

One-watchmaker assembly from A to Z

With, say, a Tudor watch, should you visit the manufacture and ask who completed your watch you would find a room filled with watchmakers pointing at each other like the Spider-Man meme. At Bovet, they do not use the now-common style of assembly line watchmaking where watchmakers at different ‘islands’ take care of one particular task and pass it on to the next stage and watchmaker. Because each Bovet watch is completed by a single watchmaker, this requires each watchmaker to have the full range of skill sets necessary to perform each task. They are experts in all facets of watchmaking. Andrew explains in the video: “Moving from station to station is with one watchmaker completing a watch from A to Z. It could be Morgan, it could be Gregory, you could ask for a happy snap of the watchmaker who actually worked on it with your movement before it gets cased.”

Where Bovet sits as a brand

Hype luxury brands. may have the most widespread and mainstream appeal, but those who truly get and understand watchmaking are often drawn to watch manufacturers like Bovet. A centuries-old brand rooted in tradition, but willing to go a bit wild in design to meet the imaginations, expectations, and dreams of its clients, the vertically integrated Bovet Fleurier SA leverages their mastery of over 43 different in-house watchmaking crafts and techniques to create distinct handcrafted timepieces that exhibit true luxury. This is why mega-collectors like Jay-Z are known to own Bovet timepieces. Because after the hype, when you have had your pick of the litter when it comes to all the big brands and their most sought-after pieces, this mainstream segment becomes stale. Bovet is a brand for those who have well and truly fallen in love with the craft of classical Swiss watchmaking and for those seeking a brand that can co-create something special that reflects who you are.

I cannot stress more how what is written here is just a fraction of what you can discover about Bovet in the video above. So, do yourself a favour and watch the full video. I promise you will walk away with a whole new perspective on a brand that, while awarded with many GPHG prizes, has not had the full time it is truly due in the broader spotlight.